Fluxless/Formic Reflow Ovens

Heller has designed and built a production ready horizontal Flux-Free Formic Reflow oven for formic acid vapor soldering. This new oven has been designed to meet Semi S2/S8 safety standards (including toxic gases).

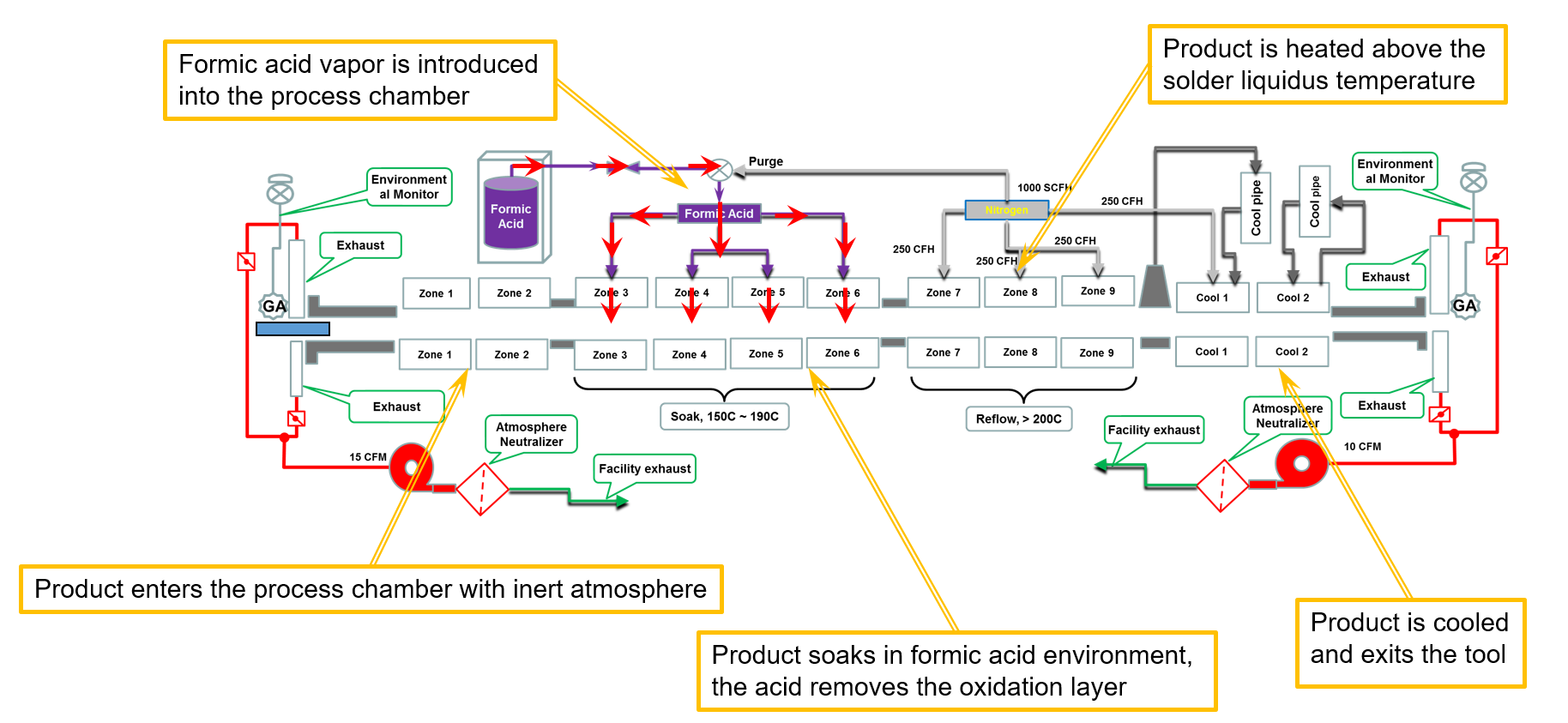

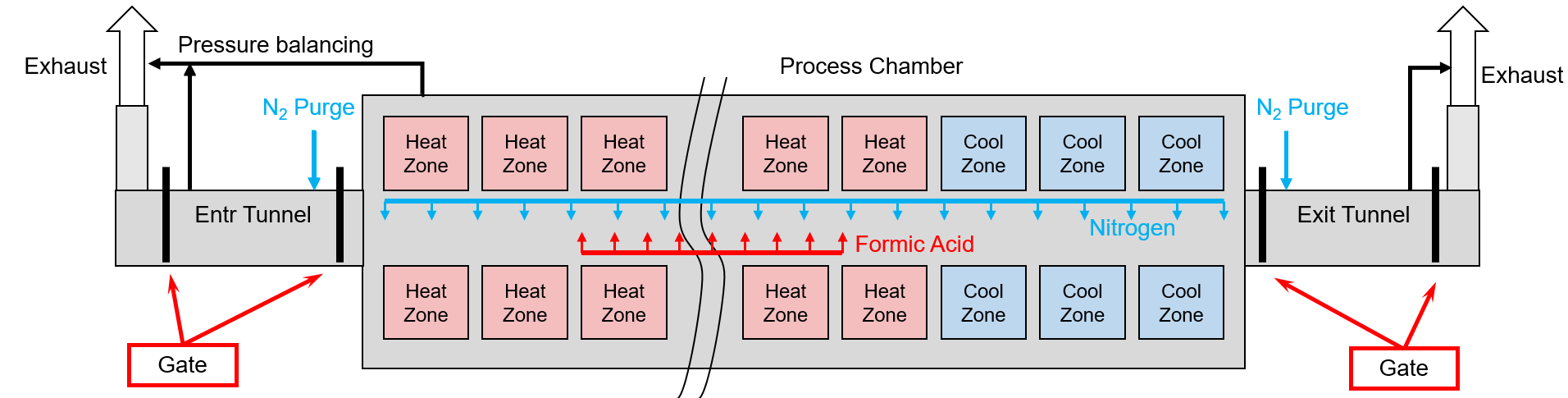

Our Formic Reflow Process. These formic reflow ovens operate like a normal reflow oven with the addition of formic acid vapor injection into key thermal zones (typically soak zones). Here the formic acid removes any oxides on the metal prior to reflow. Formic levels are maintained by a bubbler system and monitored in real time.

Formic Acid Precision Bubbler Cabinet. Our formic acid reflow ovens use a bubbler system to provide stable and consistent formic concentrations in the process chamber

- Designed to provide consistent, reliable formic acid vapor concentration to within 0.5%, ensuring a stable process.

- Formic acid vapor concentration saturates nitrogen according to Antoine equation for a given temperature. Formic acid vapor concentration in the oven can be varied by bubbler temperature and nitrogen flow through bubbler

- Auto refill system ensures bubbler never drops below minimum level

Heller Formic Gate. We have developed the formic gate system, which serves to dramatically reduce process gas consumption. Formic gate acts as sets of double doors placed at the oven’s entrance and exit. During production, only one door ever opens at a time when a product is entering or exit the machine. This isolates the process chamber from the outside, and lowers Nitrogen and formic acid consumption.

Key advantages of formic reflow include:

- Formic Reflow for High Volume Manufacturing- Our formic reflow ovens provide true in-line continuous processing, similar to that of a standard reflow oven. This provides the highest throughput when compared to batch-type competitors.

- Low Consumable Cost – These formic reflow ovens offer a unique Formic Gate feature which acts as a double set of doors at the oven’s entrance and exit. This provides low Nitrogen and Formic consumption while maintaining high throughput.

- Vacuum Process Option Available – To meet the ever increasing industry demand for void-free interconnects, an optional vacuum chamber in the reflow zone is available for our formic ovens.

- Advanced Safety Systems- These formic ovens meet all SEMI S2/S8 standards with integrated safety monitoring and abatement systems.

- Up to Class 100 Cleanroom Classification – Multiple cleanroom compatible options are available, up to class 100!

- Real-Time Continuous Formic Monitoring – Formic acid concentrations are continuously displayed and recorded for effective process monitoring.

- Leadership and Experience – Heller Industries is the technology leader who pioneered fluxless formic reflow, and was the first company to bring continuous in-line formic reflow to the market.